Flying sensors

Thanks to our innovation, farmers’ demand for key agricultural information will be satisfied by means of an extension service based on flying sensor (drone) information. The deployment of flying sensors is unique in its ability to provide farmers with real-time, high-resolution, and on-demand information. We provide essential agricultural information:

- At an ultra-high spatial resolution (NDVI)

- With unprecedented flexibility in location and timing

- Based on wavelengths not observable by the human eye

- With a country-specific business oriented approach.

To this end, we use low-cost high-resolution flying sensors (drones) in a development context to ensure that farmers will get information at their specific level of understanding, and simultaneously develop a network of service providers in Mozambique and Kenya.

A flying sensor is a combination of a flying platform and camera. Reliable flying sensors are on the market in a wide-range of categories each with its specific characteristics. Based on the consortium’s experiences over the last years low-cost flying sensors have been identified that are excellent equipped for our innovation. Typically, a flying sensor flies at a height of 100 meter and overlapping images are taken about every 5 seconds. This results in individual images covering about 50 x 50 meter and an overlap of 5 images for each point on earth. So, in order to cover 100 ha 500 images are taken during a flight.

The use of Flying Sensor is unique and no comparative techniques exist that provide farmers with real-time high-resolution information. The use of satellites to provide farmers with spatial information has been promoted but has three main limitations: they have fixed overpass times, the spatial resolution is low, and the presence of clouds halters the information. It is unlikely that, within the coming decades, progress in satellites will be real competitors of flying sensors. Another category of comparable techniques to provide farmers with information is the use of ground sensors. Typical examples of these sensors are soil moisture devices, soil sampling and laboratory analysis, crop sampling and laboratory analysis. However, all those sensor techniques have the common limitation that information is only local point representative, while the main question farmers have is regarding to spatial differences. Moreover, these ground sensors are in all cases too expensive to be used by small-scale farmers.

Flying Sensors Systems development

ThirdEye has started in 2014 in South Mozambique, notably in the irrigation schemes of Chokwe (HICEP) and Xai Xai (RBL), both in the province of Gaza. Since its creation ThirdEye has developed rapidly. In 2016 a permanent base was established in Kenya, Mery County. In 2018 another base was set up in the province of Manica, in central Mozambique.

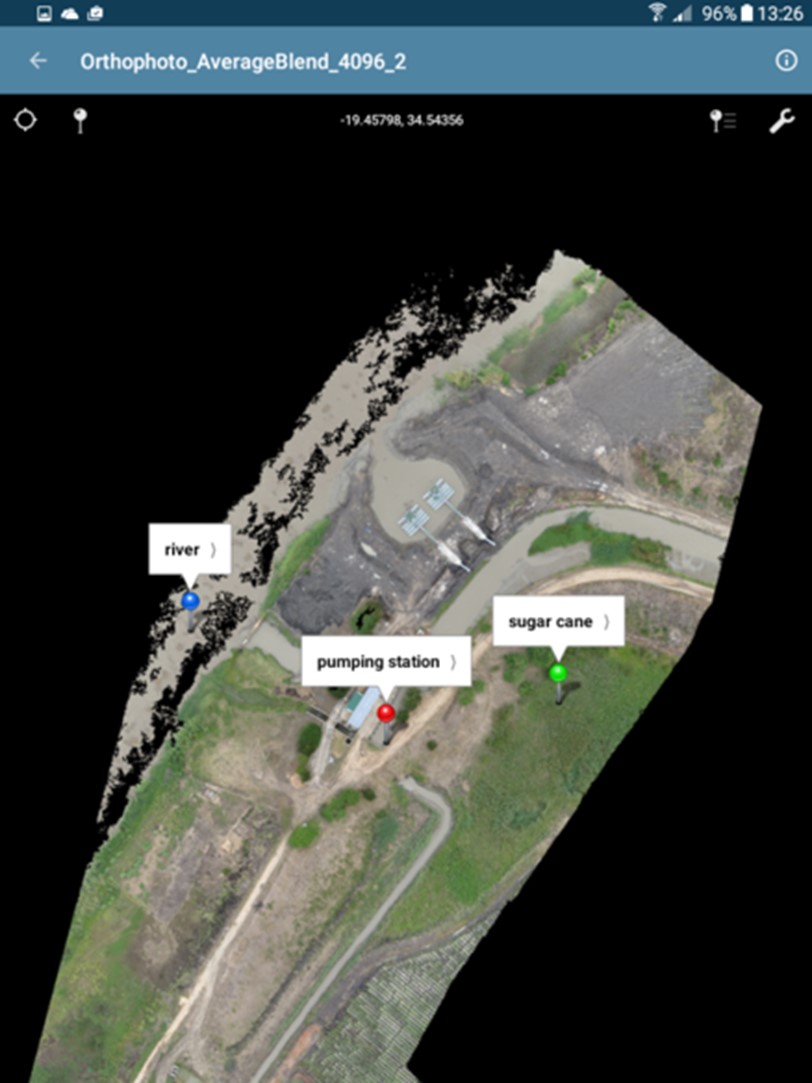

Alongside the expansion of the working area ThirdEye has gone through a technical development. At the core of our advisory service stands the Flying Sensor, alias drone. Since the beginning in 2014 the Flying Sensors Systems have evolved continuously. The changes concerned drones, cameras, (RGB, NIR), mountings, supporting equipment (ground base station), and advising tools (tablets, viewing software). Drones became lighter and more sophisticated. Cameras got to higher resolutions and speedier interval times. Mission planning and advisory viewing tools benefited from new softwares.

ThirdEye designs itself some dedicated technological innovations. In the course of the last 7 years cameras needed modifications and different mountings. An aluminium mounting system was invented which was applicable to various sensors ( RGB, NIR, thermal cams).

Most recently ThirdEye is introducing a new generation of ultra-light Flying Sensors, doped the SSmd, Small Scale mini drone, weighing just around 200 gr, at very low cost and extremely easy to use.The SSmd is capable of sending cache imagery through bluetooth/wifi.

NDVI technology

Our flying sensors have cameras which can measure the reflection of near-infrared light, as well as visible red light. These two parameters are combined with a formula, giving the Normalized Difference Vegetation Index (NDVI). This information is delivered at a resolution of 2×2 cm in the infra-red spectrum. Infra-red is not visible to the human eye, but provides information on the status of the crop about two weeks earlier than what can be seen by the red-green-blue spectrum that is visible to the human eye. NDVI is the most important ratio vegetation index and says something about the photosynthesis activity of the vegetation. Moreover, NDVI is an indicator for the amount of leaf mass, and therefore, ultimately biomass. In general, open fields have a NDVI value of around 0.2 and healthy vegetation of around 0.8. NDVI values give an indication of crop stress. This can be caused by a lack of water, lack of fertilizer, pests or abundancy of weeds.

Near InfraRed

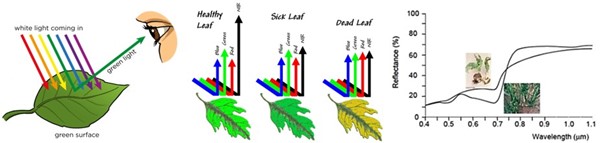

When light falls on a leaf, reflection occurs. The amount of reflection of green light (0.54 µm) is very high, making plants green to the human eye. Healthy vegetation does not reflect much red light (0.7 µm), since it is absorbed by chlorophyll abundant in leaves. In the near-infrared spectrum (0,8 µm) the amount of reflection increases rapidly to 80% of the incoming light. This increase is caused by the transition of air between cell kernels. This is characteristic for healthy vegetation.

Damaged plant material does not show this increase in reflected near-infrared light. Moreover, the reflection of red light is much higher than in healthy plant material. By measuring the reflection in these spectra, damaged plant material can be distinguished from healthy plant material (Schans et al., 2011).